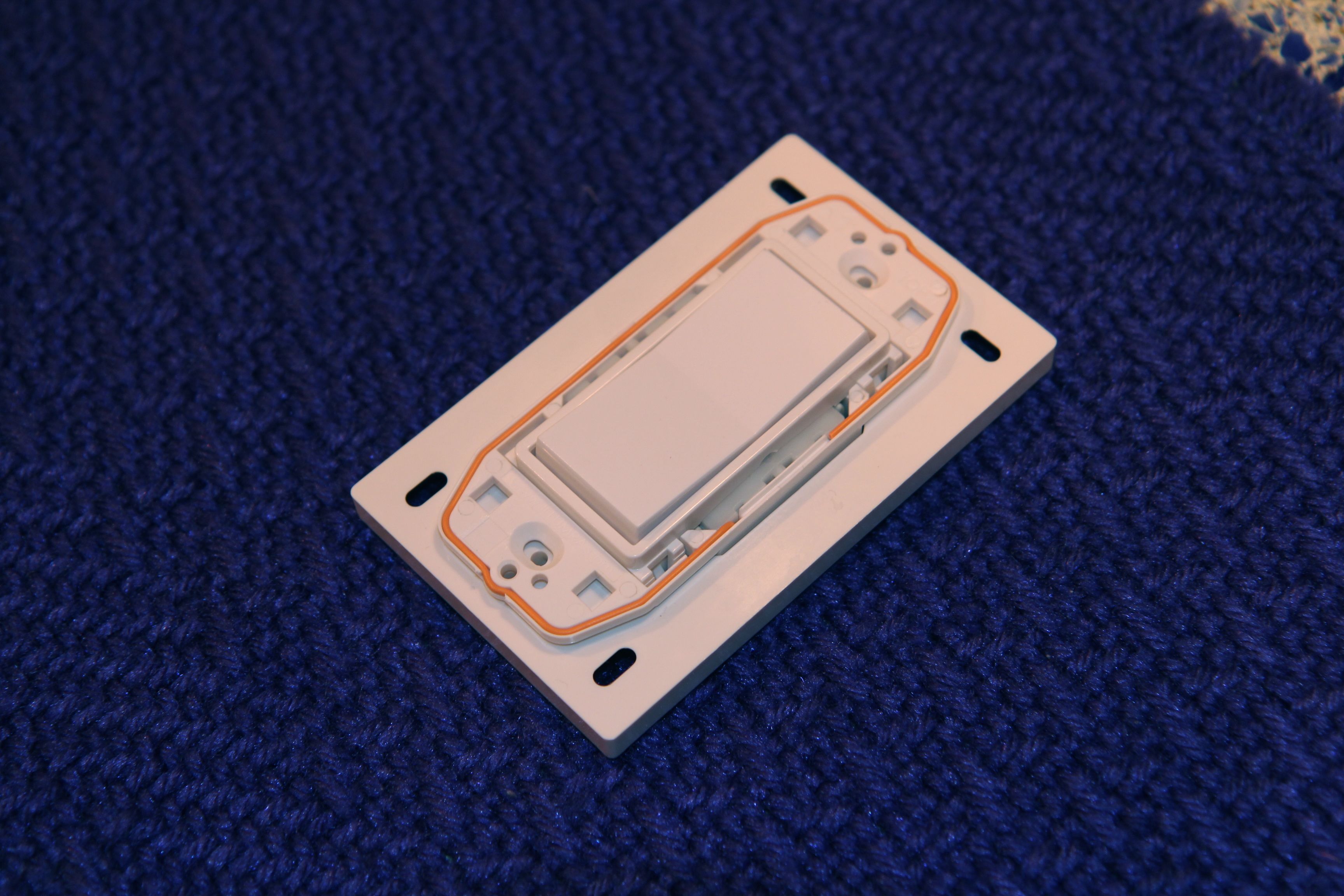

An energy-harvesting toggle switch, which will be wall-mounted. It transmits signals to a remote control without the need for batteries. The copper generator pickup coil is exposed here, wrapping around the switch perimeter.

One of the design errors I committed was underestimating the ventilation requirements of an active kitchen. It is common for an over-the-stove microwave to provide a vent fan for removing the fumes from the chemical reactions common in the preparation of certain foods. In many kitchens, the air is vented to the outside, but in our case, we are working against an inside wall, and, not wanting additional penetrations through the flat roof, the (filtered) air was redirected back into the kitchen.

This works in many cases, but evidently not for us. Portia is an enthusiastic cook, and I am an inattentive one. These both lead to conditions of high aroma concentrations, whether from her elaborate sautéed garlic and olive oil creations, or from my burnt toast episodes, both of which are detected by our exquisitely sensitive, city-inspector-required, smoke detectors.

So additional ventilation is required, and it must be to the outdoors, not just recirculated to different parts of the house. A little research resulted in determining how much ventilation is needed (air volume replacements per hour converts to cubic feet per minute (cfm) of fan performance). And the tunnel to the kitchen skylight was a perfect opportunity for an external sidewall fan, rather than figure out how to penetrate the roof.

I ordered the fan, a 250 cfm unit with a 6-inch diameter intake, capable of replacing my upstairs kitchen’s air 8 times per hour. I expected to make a 6-inch hole in the wall, mount it, wire it, and be done. As usual, it is simple in principle, but the details get in the way. I needed to move an existing outlet in order to have enough room, and there were other complications. But with enough trips up and down the ladder to get the next required tool, and the desire to avoid smoke alarms in the middle of dinner parties, I was able to mount the fan and its intake duct in the course of an afternoon.

Because this was not part of the kitchen-remodeling plan, there was no provision for wiring a ventilation fan. Fortunately, I had instructed the electricians to bring power to an outlet on the outside of the skylight hatch, and this is what I used to power the fan, but the control, the on-off switch, did not exist for it. Running a new wire would be very difficult now that the walls and cabinets were in place.

Ah, but I had acquired some interesting remote controls that might solve the problem. They utilized what is called “energy harvesting” technology. This is a current trend and research area where small amounts of energy are obtained from the environment to do intermittent tasks. These include solar cells and thermal junctions and strain gauges. The one that I obtained was a contemporary styled “rocker-switch” which, when you push on it, causes a spring to snap a magnet past a coil, generating a small voltage, which briefly powers up a circuit long enough for it to transmit a code over a wireless channel to a receiver. The receiver recognizes the code as either a signal to turn ON or to turn OFF a relay that powers the remote device.

It’s all quite amazing, because the entire sequence happens in a few milliseconds, and no external power (wiring or batteries) is needed. And it worked great as the fix to my design oversight.

The exhaust fan now works by this remote control. It is not silent, but it is powerful, and I am looking forward to my next episode of overcooked bacon to see how long it takes for the smoke alarm to be silenced.