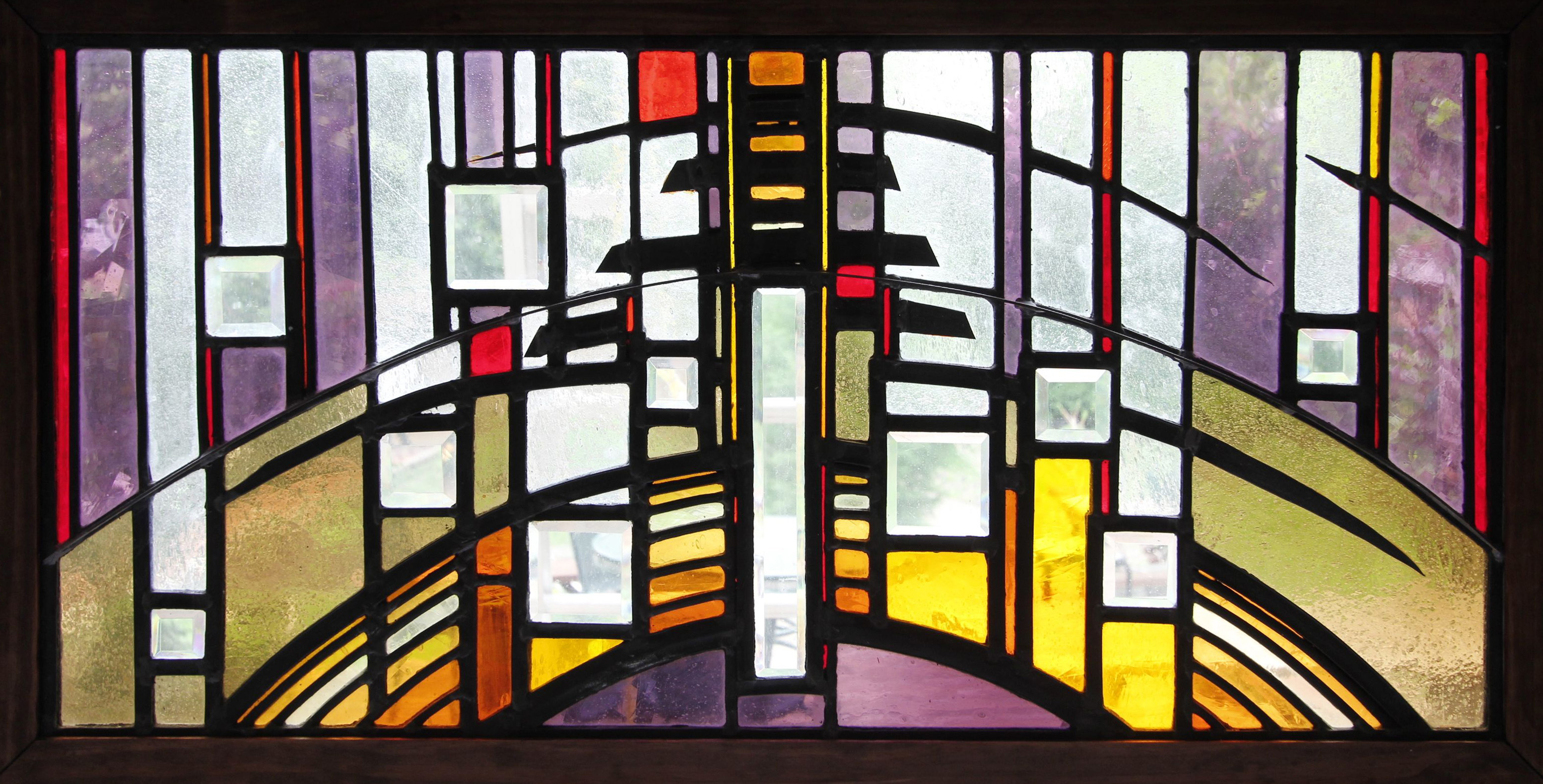

- In the afternoon light, after a one-year makeover.

July 7 2013. A year ago, I hosted the “Before” Party. I had just taken ownership of This Odd House, and was making my plans for it and wanted to have people see it in its “before” state. The responses I got ranged widely, from enthusiastic support to expressions of concern over my mental health, from “awesome, don’t change a thing” to “run away, run away, as fast as you can”.

I didn’t heed any one person’s advice, but took counsel in all of it. A year and a savings account later, where am I?

Well, I am not where I expected, which is to be “completed”. As was entirely predictable (and many did), the project was much bigger and more expensive than I thought. Some of it was reasonable, scope-creep occurs in every project.

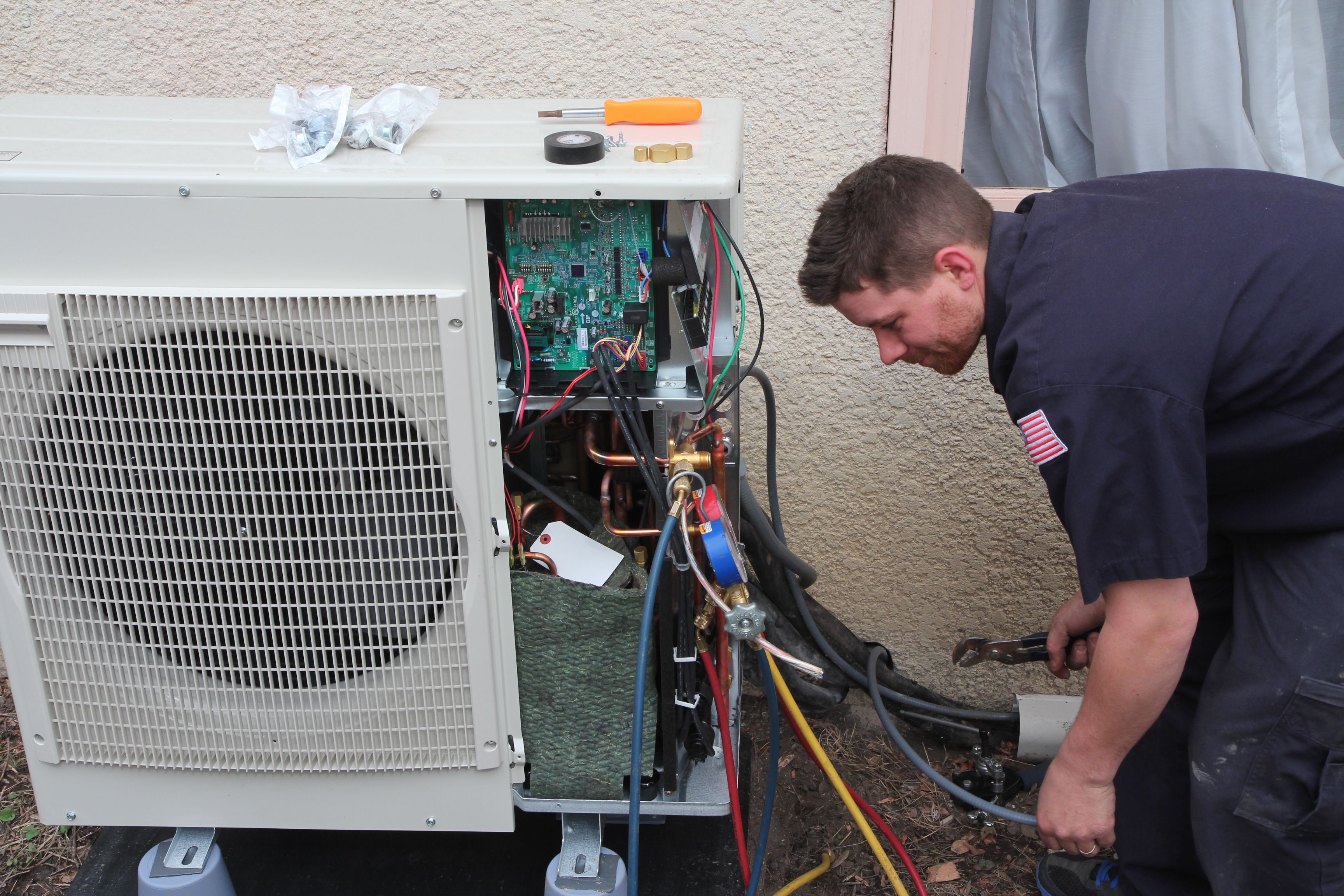

Much of it happens because opportunities arise that, if not taken, would incur greater cost later. When the walls are open, and expose bad plumbing and rotting floor joists, it would be foolish to not make the repairs.

That was a case of unexpected discovery and mandatory repair. There were also moments of esthetic opportunism. When the ceiling is open for ventilation work, why not also install a solar light tube to bring daylight into a windowless bathroom? Not in the original design concept, it is an example of scope creep, but one that was deemed worth it. If the budget constraint were perfectly rigid, it would have been a far less satisfying, even frustrating, project. But that was not the life experience I was after.

There were larger “misunderestimates” of the project. It was pointed out to me at the Before Party that my Eurovan would not fit in the garage. This was an unpleasant surprise! I knew that someday the garage would need to be updated, but I had not considered that it would be completely useless in the meantime. I would like to replace it with a modern garage, one that has a nice workshop bay, but it will have to wait for another year.

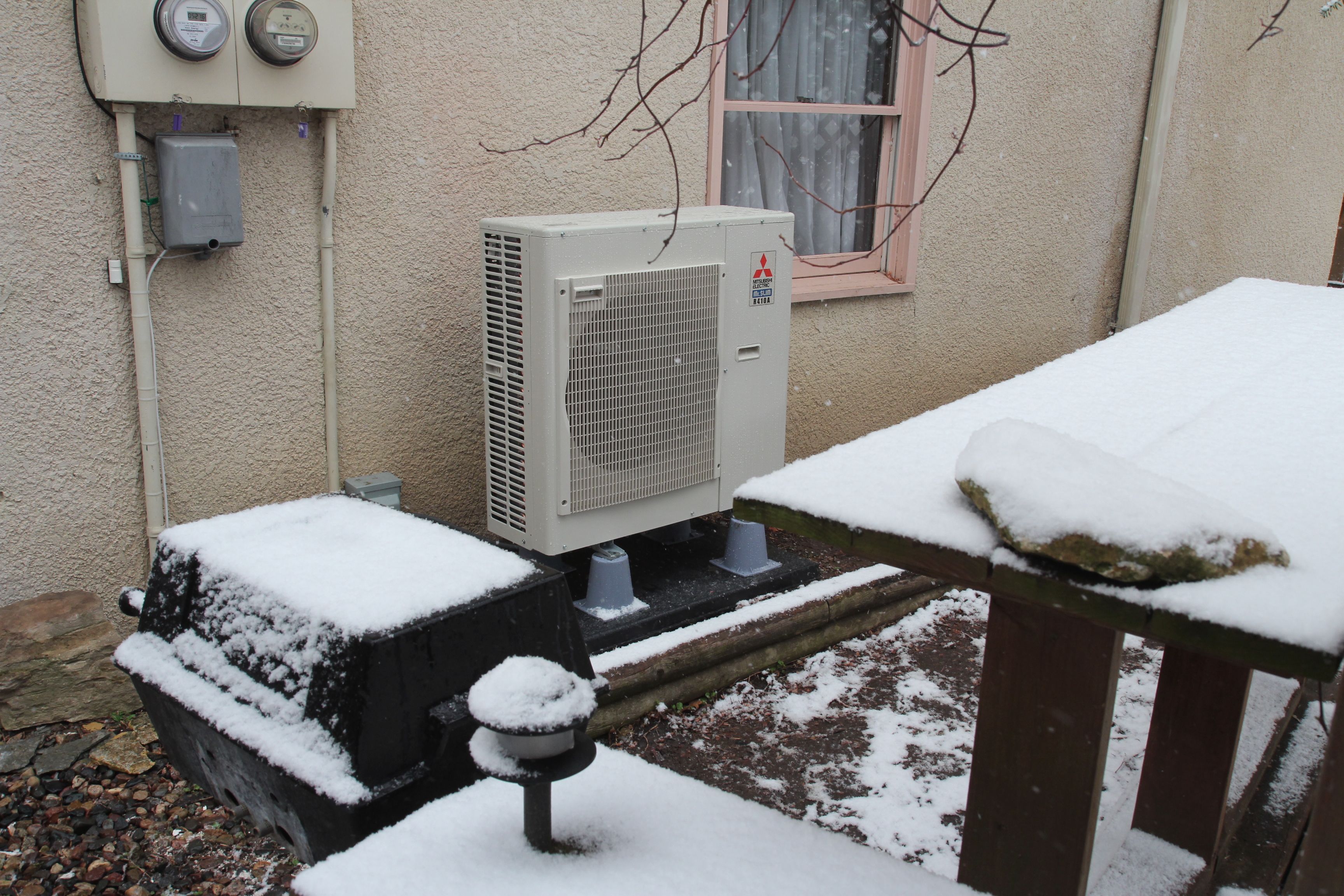

I had also expected to have an array of solar collectors on the flat roof. I have been working with Innovative Power Systems, which applied to Xcel Energy on my behalf for their renewable energy rebate program, but the bureaucratic wheels grind slowly, and I have not heard on whether it has been approved. Probably for the better, there are many other renovation items to finish.

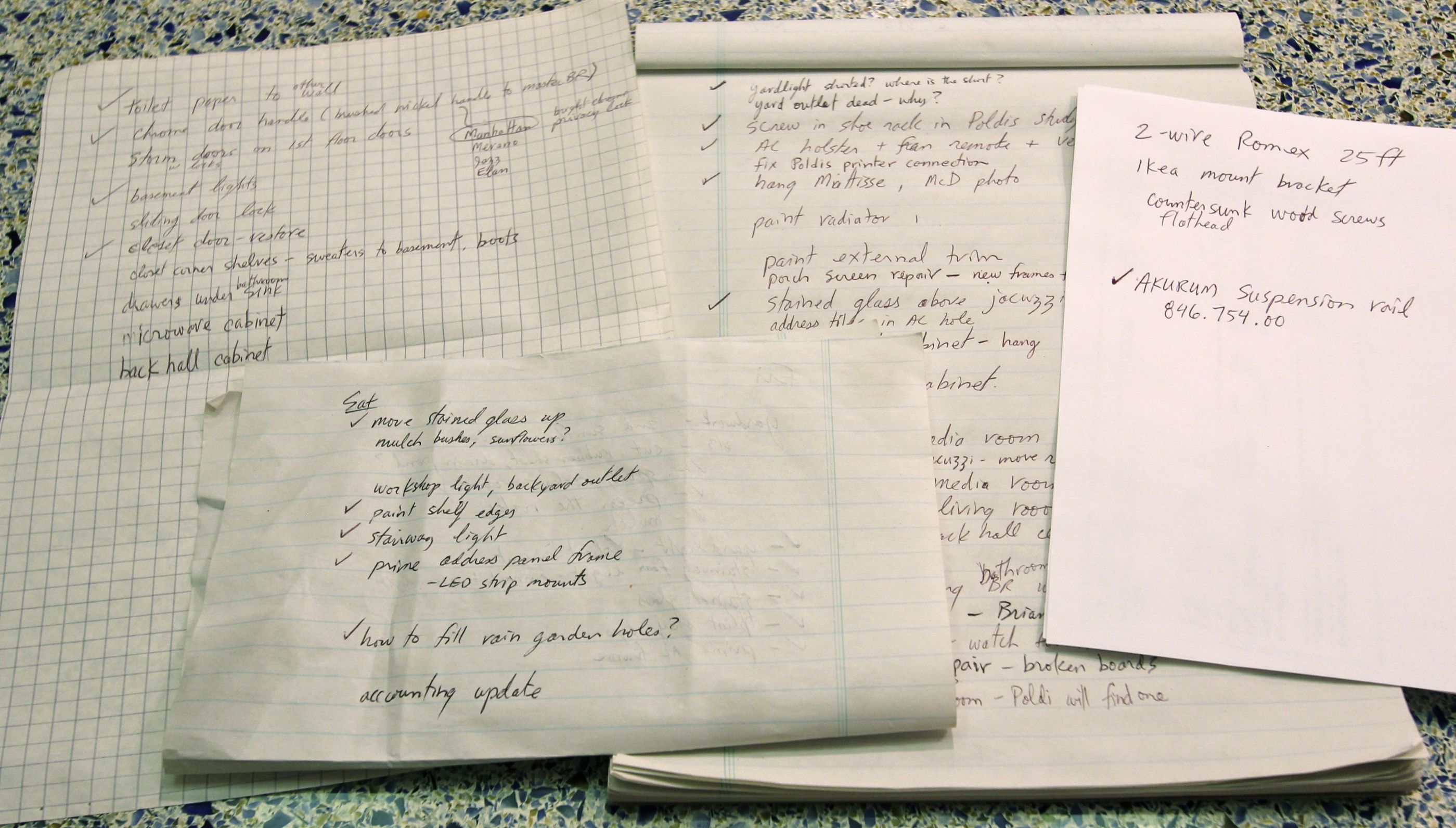

The punch list of remaining projects is hydra-like. Each item seems to spawn at least two more before it can be checked off. The nature of the items has shifted however, from things that are clearly new design and construction (providing kitchen ventilation) to things that mark a transition to normal maintenance (painting and deck repair).

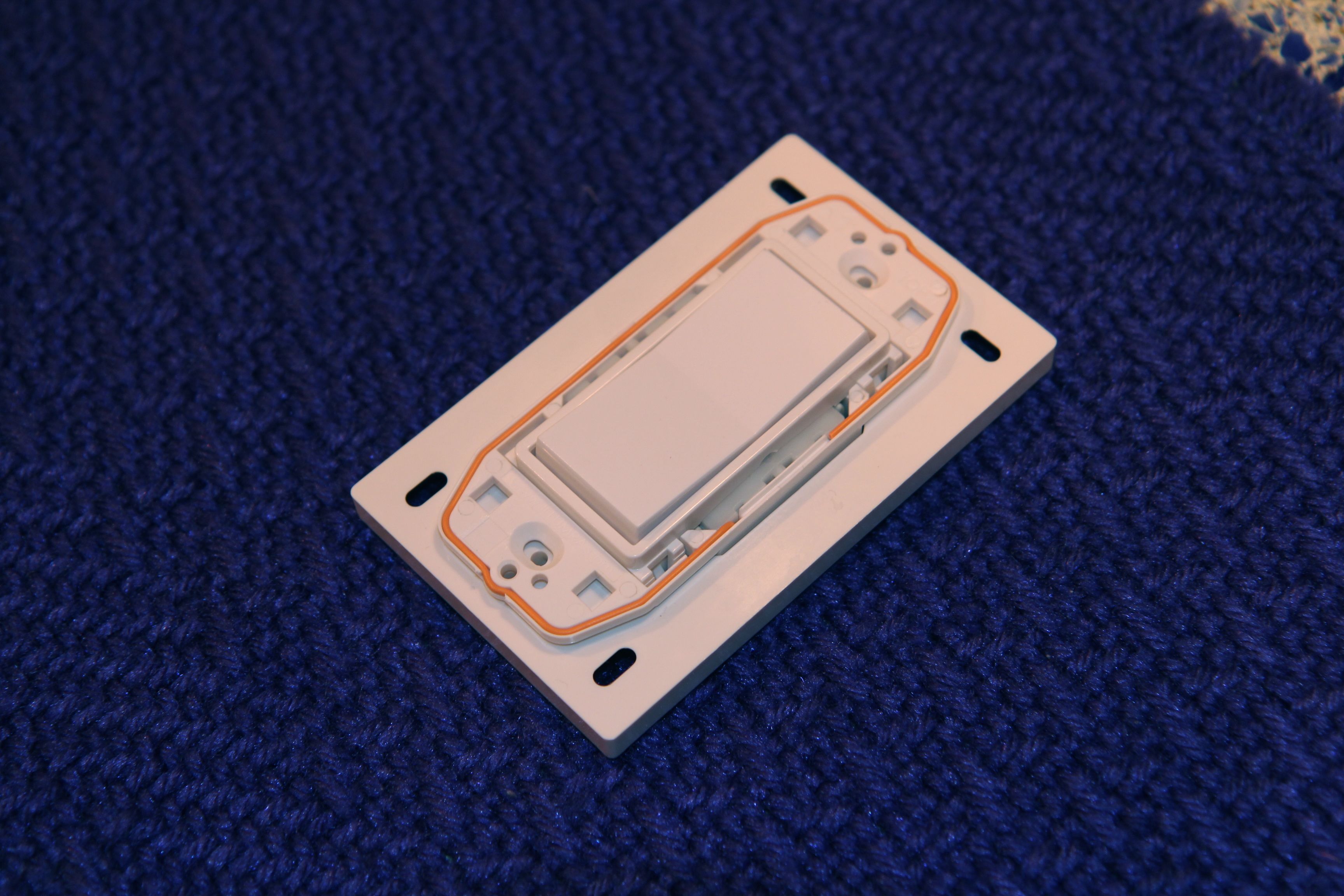

The year has provided yet another interesting chapter in my life. I got to invoke and satisfy my design urges; I acquired a much deeper knowledge and appreciation for modern construction materials and methods, and lessons in how houses work. They are far more complex than one might expect, with subtle details that if not attended to properly can create subsequent problems.

As an engineer, I sometimes overestimate my abilities to analyze and solve problems. Renovating This Odd House has been humbling. Having seen the handiwork of amateurs (including me), I am no longer reluctant to seek help from professionals; even the clerks and assistants at hardware and home stores have specialized know-how that I now try to tap into.

The year has included a transformation of lifestyle. Initially living comfortably in a townhouse, I started the demolition and renovation of TOH as an off-site property owner. Then I moved into the thick of it, not truly moving in, but bringing my possessions into holding zones, and beginning a twelve month bivouac while construction activities ensued around and sometimes within my camp. Essential tools were located and utilized, but the cry to this day is still “I know I have it somewhere, I just don’t know where”.

My interrupted lifestyle changed again when Portia joined me at the camp, bringing her worldly possessions to be interred alongside mine. We improvised mightily as construction continued, braving the occasional heat, water, and electrical outages as the infrastructure in This Odd House was replaced and renewed.

Major combat operations are now over, and our possessions and activities have diffused into the newly opened and remodeled spaces. It has been an organic process, not planned or optimized, but we now occupy the space and architecture I envisioned a year back—an open feeling with natural lighting and clean stylings of contemporary design, built within and despite, the constraints of an old and awkward structural framework.

I like the neighborhood and community in which we are embedded. We are gradually knowing our neighbors, and the foot traffic past our house to the light rail train is a reminder of one of our great benefits: easy access to downtown and the airport.

Yes, there has been much that has changed in the last year. I sometimes forget how it once was, and how different it is now. I look forward to showing it to the Before Party attendees: they may be impressed at the transformation. For others it might be just another banal exercise in interior decorating updates. I may have tried to “turn a sow’s ear into a silk purse”. Fortunately, even though the result is no silk purse, I will be enjoying the outcome of the effort for many years.

My life has evolved and changed with This Odd House over the last year. I had always planned to have an “After” party, but I must now acknowledge more than just a year of renovation. I now have a new life partner, baptized in the unpredictable waters of plumbing repairs and heating outages. We both will be celebrating milestone birthdays in August, and acknowledging a commitment to live together in This Odd House. The After Party has now been expanded and enhanced into “The (happily ever) After Party”.

One year on: it was a good year, let’s have some more.