The furnace, or more properly, the boiler, since this is the term used to describe the heating plant that generates hot water for heating a house, has now been replaced. The previous unit had held up for half a century, and could probably have gone another many decades, but its efficiency in converting the latent energy of natural gas into useful home heat was low, maybe 50%.

Unfortunately, substituting a modern high efficiency boiler is not cost effective. The expense of the new equipment, and the labor to install it, far exceeds the winter heating bill, even looking many years ahead. This is an obstacle to reducing our country’s carbon emissions and dependence on finite fossil fuels. The immediate economic benefits do not yet warrant the conversion expense.

But I had other objectives. I was eliminating the requisite chimney, reclaiming its volume and floor space, and saving some of the expense of repairing it. I was fulfilling a moral choice to become a more energy efficient citizen of the planet. I was bringing an old house up to date to provide shelter in a new century. I was taking on a renovation project at a point in my life where that project was providing a renovation for me. These are intangibles, not subject to strict fiscal accounting optimizations.

I obtained several bids for the job. All caused a gasp when first reviewing them. Modern boilers capable of keeping This Odd House warm through a Minnesota winter are approximately $5000 and require another $5000 to install. Mine was a bit more, because I had removed the asbestos-clad main feeder pipes, and that part of the house infrastructure had to be rebuilt. To be fair, these costs included replacing the about-to-fail old water heater with a “boiler-mate” tank that ran off the main heating plant.

I chose a local plumbing and heating company, a father and son team that seemed to have a lot of experience with low overhead. The process of installing the new boiler took four working days! The first day saw the removal of the old water heater. On a Friday. For the next week, it was cold showers only.

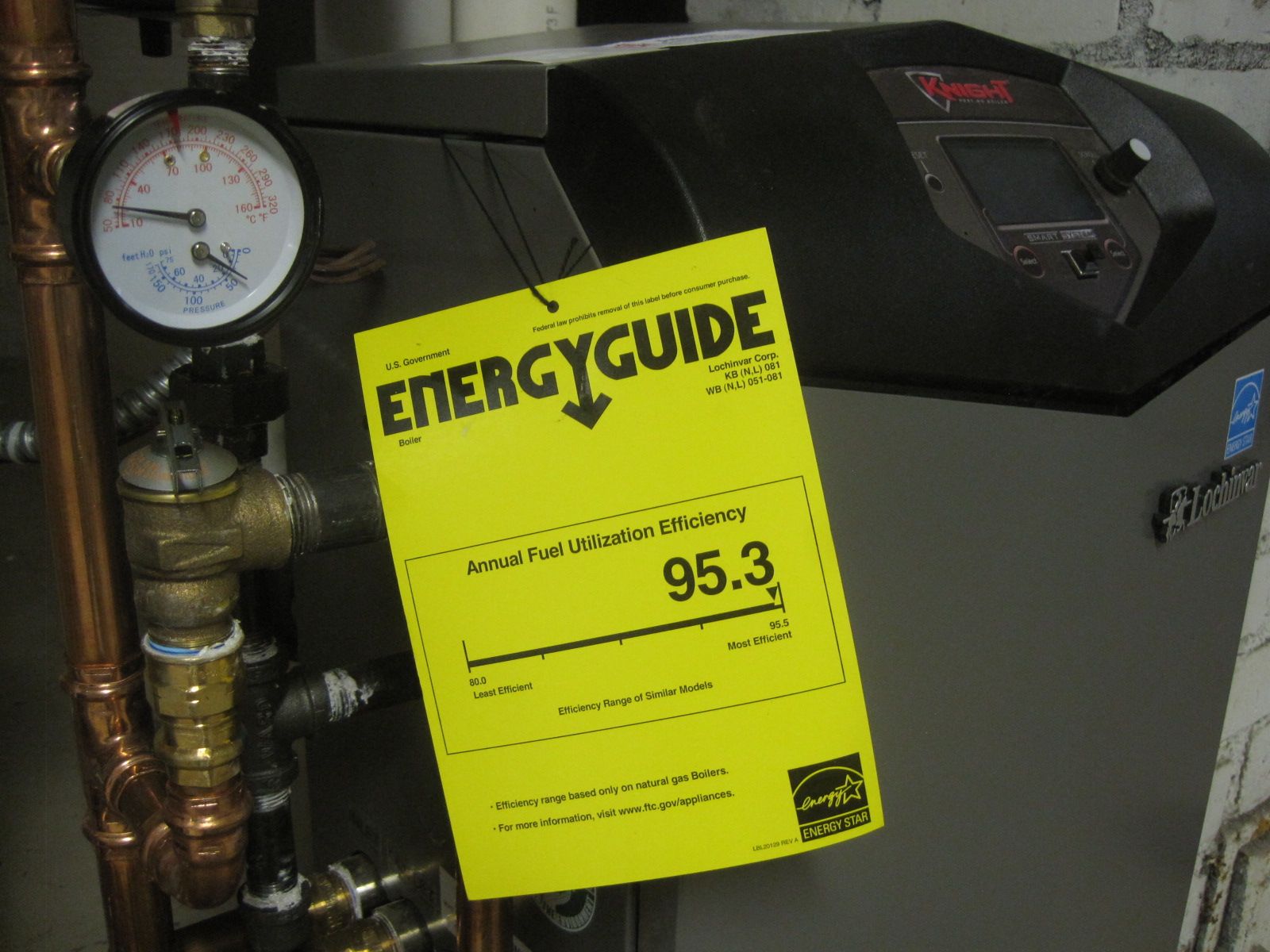

The new boiler is a testament to modern energy engineering. What previously required a vault-like fire box the size of a refrigerator and a tank suspended from the ceiling, now needs a miniature unit not much larger than a desktop PC. In fact there is the equivalent of a PC in there, busy optimizing all of the combustion and heat demands of the system.

The four days of installation is an indication of the scale of the project. Early on, the air supply and exhaust flue needed to be routed. Modern heating plants don’t need chimneys anymore; their exhaust temperatures are low enough to be vented through common PVC pipes to a convenient sidewall. In my case the nearest sidewall happened to have 18 inches of concrete in the way, the foundation of This Odd House. Ryan Johnson, the son, claimed that he had never taken more than two hours to install the venting pipes. Two hours later, he was still chiseling to reach the exterior of the house.

The water heater, previously a self-contained gas burner itself, was replaced by a heat exchange system provided by the new boiler. All the interconnections between “boiler water” (the heat source to the radiators) and “hot water” (the water we drink and wash with from the tap) had to be plumbed, never the two to meet or mix. All in all, over 150 plumbing connections needed to be made, all of them to be water tight and perfect.

It’s small, it’s complex. This interconnected system now runs the heat and hot water for This Odd House.

The result looks like Rube Goldberg to me, but I’m sure it makes perfect sense to a HVAC professional. And it looks like a modern home heating system. The best part is the tag that boasts 95% efficiency. If I must burn fossil fuel, at least I am squeezing out nearly all the energy it contains.