The windows in This Odd House have a long history. I have been able to piece together parts of it. And now I am about to become a part of their history.

The building started out as a store with living space above it. The windows were standard at the time—double hung, cast iron weights inside the frame, a rope over a pulley to counterbalance the lower window, the upper window friction fit to its track. Maybe there were storm windows, to be installed in the fall, taken down in the spring, but probably not (this was 1910).

Sometime in the last century the store was converted to a duplex. It may have been at this time that the mansard roof feature was added as an attempt to make the building look a little less like the common corner store, and more like a place where families lived.

The mansard and its window recesses appear to have been done by amateurs, or at least by someone on a very tight budget. The framing used interior grade wood, the sill flashing was pieced together, every nail penetration an avenue for water to trickle into the structure. The wooden sidewalls cut and fit so that the bottom would wick the water standing on the sill, contributing to its eventual rot.

Somewhere along the way, the windows were refurbished with “inserts” that replaced the pulley and weight system, and aluminum storm windows were added. This probably extended their usefulness a few years and improved on the heat loss, but it was done with lesser quality materials, and eventually the inserts or combination windows or both failed to keep out the cold, and the residents at the time elected to seal the cracks. Permanently. Sealant and paint now hold the double hung windows in stasis, preventing them from being opened to admit cooling summertime breezes.

By the time I acquired the house, the interior between the window and its outer storm window, impenetrable by humans, but completely accessible to insects, became home to paper wasps. Broken panes could no longer be replaced; they had been repaired by a bead of silicone, administered from a caulking gun, following as best as possible the crack in the glass, hoping to hold the fragments together for another year or so.

And so it is up to me to bring this house into the next century. I had estimated that I could replace the windows at $1000 each, mentally adding that to the purchase price of This Odd House. As I investigated the pricing of modern windows, I realized I had once again underestimated. The low bid was 1.5x my guess, but I ended up going with a contractor at 2X. And I am glad I did.

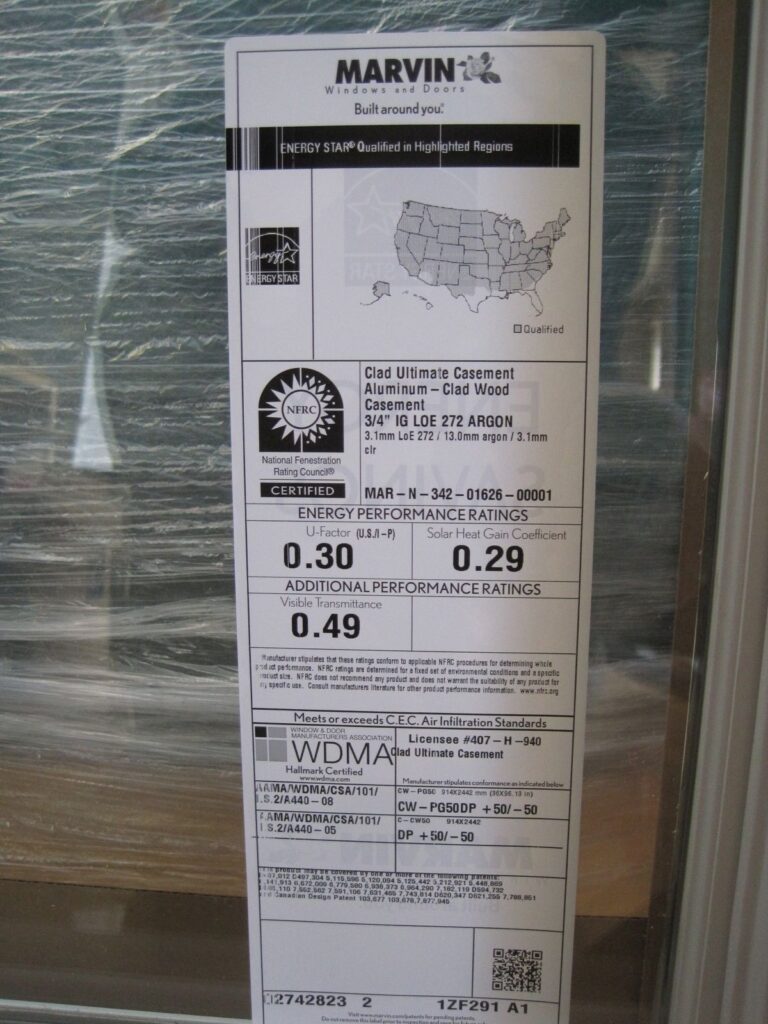

Modern windows are high-tech semi-wonders of our age. Storm windows, which cut heat loss by creating a stagnant insulating air volume, have been replaced by double pane glass with a small gap filled with argon gas. At one time I scoffed at this concept, thinking that the thermal properties were only a little different than air, so why would you go to the trouble of making a window that was destined to eventually leak and replace the argon with air anyway?

Well that was over twenty years ago, and high end windows are still filled with argon, a noble gas that is monatomic (oxygen and nitrogen are diatomic, a big thermal handicap). And my old thermos bottles still work, somehow keeping hot things hot and cold things cold, so evidently argon filled windows were not just a fad of the nineties. Maybe they actually work.

And so with my goal of renovating This Odd House to become energy efficient, it makes sense that this is the time to replace the old windows. After a hundred years, they have performed their service. It is time to bring on Windows 2.0.

I contracted to have casement windows made by Marvin replace the double-hungs. They provided a clear full view of the outside world. Metal clad exteriors that (claim to be) maintenance free, a contemporary look inside, and a mechanism to fully open the window into its mansard frame make it a great improvement, at least in the eyes of this owner.

The installation is what made the overall expense higher than I expected, although I am now becoming accustomed to the hidden consequences of renovating an old house. Almost everywhere I have turned to fix or upgrade some aspect of this old architecture, I have encountered prior obsolete or poor construction practices or obstacles that have made the renovation more difficult and more expensive.

In the case of the windows it was the outside sills that created problems. The recessed windows in a mansard roof have a large “apron” or sill at the bottom that collects water and especially snow. The best sill is a sloped single sheet of metal that has been formed into a pan that wraps around the bottom of the window, is impervious to water, and sheds the snow. In contrast, the sills in This Odd House were multiple sections of galvanized metal, pieced together and nailed into place.

Over the years, the water had penetrated and rotted the wood in the mansard structure below and around the windows. All of these areas now needed to be replaced. The new construction repaired the rotted wood. It also provided a new metal sill, not the perfect single part (impossible to fabricate to the window tolerances), but a two-piece overlapping system, installed with sealants rather than penetrating nails.

Each of the old windows that the carpenters pulled out represented a new and unique restoration challenge. Each was assessed, repaired and reconstructed to modern construction practice. Water is the enemy, and construction materials and methods have evolved to high levels to combat it.

I have more work to complete in my living space on the second floor, but I am excited to see the new windows installed. After months of less visible infrastructure (boilers and roofing), it is very satisfying to look through a large clear window, a big visible step in the renovation of This Odd House.

Click a thumbnail below to see the gallery.

We are neighbors…my family and I live on 31st a few houses down from Chris and Rob’s. I remember seeing when your house was for sale; I am so glad someone who cares about it has moved in! I grew up in the suburbs, but love the city and belonging to a neighborhood too. Good luck with the projects and getting settled in!

My home has a mansard with window recesses similar to yours, and it is time for refurbishing. Your article is the only one I’ve seen that says basically how to do it. You said your “new metal sill, not the perfect single part (impossible to fabricate to the window tolerances), but a two-piece overlapping system, [was] installed with sealants rather than penetrating nails.” Could you elaborate somewhat on this? I might assume you said this because you considered a single-piece too difficult to bend the flanges at exactly the right distance apart to insure the piece to fit properly into the recess. Am I correct in assuming this? Also, since I can’t detect from the photos where or how much the two pieces overlap, am I correct in assuming that basically the overlap occurs across the whole apron? It seems that this is the best way to overlap, and I think this is what you did. Could I ask what type of sealant you recommend? Hope the bond lasts forever! I appreciate any help you can give me on this! The sides on my recesses are plywood also, and not in great shape, so I plan on covering them with metal also. Thank you so much for sharing your project and your reply!